1. DIY Powder Coat Spray Booth Equipment Overview

A DIY Powder Coat Spray Booth is a cost-effective enclosure built to contain overspray and improve coating quality. Basic components include a metal or wooden frame, ventilation fans (200–500 CFM), disposable filters, LED lighting, and a grounded workspace. Optional upgrades include cyclone filters for powder recovery and adjustable airflow dampers.

2. Applications of DIY Powder Coat Spray Booths

Ideal for hobbyists, small workshops, or auto enthusiasts coating motorcycle parts, tools, or furniture. Compact designs (4x4 ft to 6x8 ft) fit garages or backyard sheds, offering a safe space for low-volume projects.

3. Cost of Building a DIY Powder Coat Spray Booth

Basic setup: 300–800 (using plywood, box fans, and furnace filters).

Mid-range build: 1,000–2,500 (adding cyclone filters, explosion-proof lighting).

Advanced DIY: 3,000–5,000 (professional-grade ventilation, stainless steel walls).

Commercial alternatives cost 5,000–15,000, making DIY plans 70–90% cheaper.

4. How to Use a DIY Powder Coat Spray Booth Safely

Ground the booth and workpiece to prevent static sparks.

Position fans to create negative airflow (80–100 CFM/sq.ft) for overspray control.

Wear an N95 respirator, gloves, and anti-static clothing.

Replace filters after 5–10 uses to maintain airflow efficiency.

5. How to Choose the Right DIY Powder Coat Spray Booth Design

Workspace size: Opt for foldable designs if space is limited.

Material durability: Use galvanized steel or fire-retardant wood for longevity.

Ventilation needs: Calculate CFM based on booth volume (e.g., 8x8x8 ft booth requires 512 CFM).

Budget: Prioritize safety features like grounding and fireproof lighting.

6. Safety Precautions for DIY Powder Coat Booths

Avoid flammable materials (e.g., PVC) near the booth.

Install spark-resistant fans and explosion-proof switches.

Keep a fire extinguisher nearby and ensure proper grounding.

Test airflow with smoke pellets to confirm effective ventilation.

7. Cost-Benefit Analysis of DIY vs. Commercial Booths

DIY booths save upfront costs but require regular maintenance. Commercial units offer higher powder recovery (90%+) and durability, while DIY setups suit infrequent users. Modular DIY designs allow gradual upgrades, balancing cost and functionality.

8. DIY Powder Coat Spray Booth FAQs

Q1: What’s the best filter for a DIY powder coat booth?

A: Use MERV 11–13 pleated filters (20–50) for 70–85% efficiency; replace every 10–15 cycles.

Q2: Can I use a box fan for DIY booth ventilation?

A: Yes, but modify it with a metal housing to reduce fire risks.

Q3: How to ground a homemade powder coat booth?

A: Connect copper wire from the frame to a grounded rod or electrical panel.

Q4: Are DIY booths suitable for automotive parts?

A: Yes—ensure the booth is large enough (6x6 ft minimum) for panels or wheels.

Q5: How to reduce DIY booth maintenance costs?

A: Install washable pre-filters and clean them weekly with compressed air.

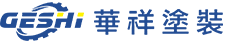

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com